Company Advantage

Refining for fermentation, cultivating for innovation - the core commitment of Jiangsu Mike Biotechnology

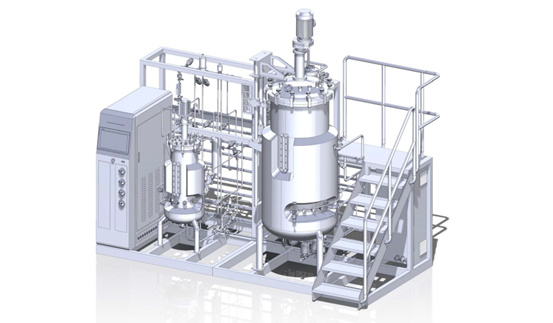

Process design: Professional customization to solve industry problems

Mike refuses "standard templates" and focuses on non-standard customized design

- Non-standard customization: Matching system parameters based on your strain and fermentation needs.

- Professional design team: With professional designers specializing in containers, mixing, fluid, and 3D, and rich practical experience.

- High requirements: Refer to GMP and ASME BPE design specifications;

- Hygienic design concept: No sterilization dead corners, no liquid residue, reducing the risk of contamination.

- Standardization: Safety, reliability, economy, operability and environmental protection.

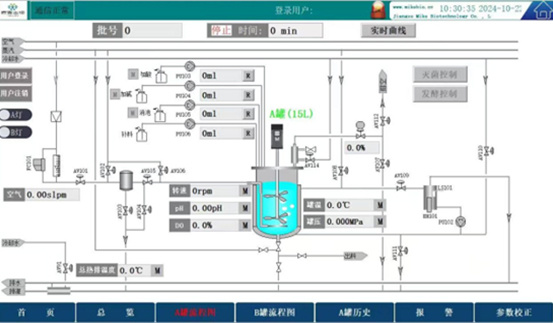

Electrical design: Precise control, intelligent connection to the future

Data is the lifeline of fermentation, and stability is the foundation of production

- The selection of mainstream and general-purpose components eliminates the worries of high prices or unavailability of spare parts.

- Electrical appliances and cables inside and outside the cabinet are installed neatly and cleanly, meeting the requirements of relevant standards.

- Complete and standardized as-built drawings and documents are available for later maintenance and reference.

- The equipment is equipped with IoT functions as standard, enabling remote fault diagnosis and convenient and quick program updates.

- Precise control of process parameters: temperature ≤ ±0.2℃, stirring speed ≤ ±2rpm, pH ≤ ±0.03.

- Optional Echosmart integrates DOE and big data analysis functions, and can display OUR, CER, KLA, RQ, etc. online.

Manufacturing process: Micrometer-level craftsmanship, millimeter-level reliability

Good equipment starts with the precision of a single screw

- It has the equipment and tools required for the installation of complete sets of projects, including various machine tools, fully automatic argon arc welding machines, automatic polishing machines, automatic cutting machines, and flaw detectors.

- The precision of manual polishing can reach below 0.1μm, and the precision of machine polishing can reach below 0.4μm.

- 100% argon gas protection during welding can effectively prevent oxidation and nitridation, improve weld quality, and is suitable for equipment with high cleanliness requirements.

Installation process: Details make efficiency, modules empower flexibility

We install not only equipment, but also ten years of worry-free productivity

- Modular polishing: The overall brushed finish creates a matte surface that is less prone to fingerprints after touching, reducing cleaning frequency and maintenance difficulty.

- Pipe production: Pipe layout without dead corners, self-flowing without residue, overall layout is easy to operate, and equipment is easy to use.

- Welding: Pipes in direct or indirect contact with materials use argon-filled single-sided welding and double-sided forming, with no residue inside the pipes.

- Pipe racks and platforms: Multi-stage fermentation uses modular assembly, facilitating later maintenance and adjustments for multiple processes.

After-sales service: Commitment is not a slogan, but a 48-hour rush

When the equipment alarm light is on, what you need is action, not comfort

- We promise to provide telephone technical support within 2 hours after receiving the buyer's fault consultation and repair; for faults that cannot be solved by telephone support, the seller promises to send professional engineers to the site within 48 hours to solve the problem (domestic).

- A complete set of standardized drawings will be provided upon delivery, so maintenance will no longer be "blind".