CIP Cleaning System

Case Details

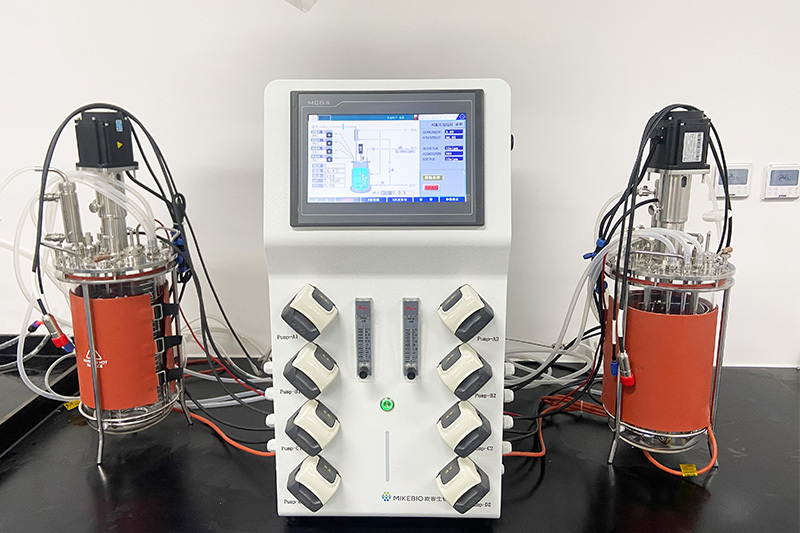

Product Introduction

This system is suitable for automated internal cleaning operations of fermentation equipment and related pipeline systems. It supports process-oriented and controllable management of cleaning operations, suitable for standardized cleaning management scenarios in liquid process workflows.

Product Features

• Efficiency Optimization: Automated cleaning helps reduce manual operation time and labor intensity.

• Controllable Cleaning: Standardized procedures support setting and adjusting cleaning parameters (temperature, time, mechanical force, chemical force, etc.), enhancing process controllability.

• Consistency and Reliability: The automated system provides consistent cleaning results, reduces human errors, and ensures each cleaning meets standards.

Product Specifications

| Model | MKY-CIP |

| Capacity | 60—10000L |

| Material | Stainless Steel 316L or Stainless Steel 304 |

| Surface Treatment | Interior: Mechanical polishing with roughness Ra0.28~0.6μm, passivation or electro-polishing (optional) |

| Exterior: Matte finish with roughness Ra0.6~0.8μm | |

| Pressure | Atmospheric pressure or pressure vessel (-0.1~1Mpa) |

| Structure | Single-layer cylinder / with jacket / with jacket and insulation - three options available |

| Configuration | Thermometer, level gauge, sanitary manhole, air breather, sight lamp and sight glass, universal rotating cleaning ball, etc. Special configurations can be made according to customer requirements. |

| Control | Full-process automatic control, monitoring, alarm, historical data reports, and curve output can be realized. |

keyword: CIP Cleaning System

Category: Biopharmaceutical Equipment

Recommended Cases

Contact: Manager Sun 18005282900

Contact: Manager Xu 18061190011

Company phone: 0511-85936307

Email:lk@mikebio.com

Website: www.mikebio.com

WeChat Official Account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.