Introduction to an organic fertilizer bioreactor

Release Time:

2021-09-08

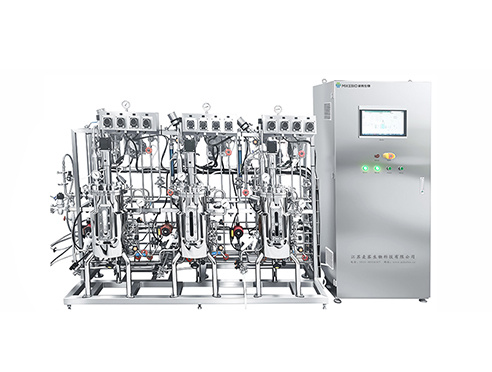

The organic fertilizer bio-fermentation tank is an important piece of equipment for effectively degrading manure into organic fertilizer. Unlike composting fermentation turning machines, the organic fertilizer bio-fermentation tank is a sealed fermentation container. The fermentation materials are pollution-free and odorless throughout the entire process, the fermentation cycle is short, and the entire process is intelligently operated. It is a good choice for organic fertilizer enterprises to achieve environmentally friendly production.

Manure fermentation is a process that uses the life activities of fermentation bacteria to degrade organic matter and uses the heat generated by fermentation bacteria to kill harmful pathogens and other harmful substances. During continuous reproduction, fermentation bacteria consume organic matter and residual protein in the manure, while producing large amounts of ammonia, carbon dioxide, and water vapor, and releasing a large amount of heat, thus increasing the temperature inside the sealed tank. When the temperature rises to 60 degrees Celsius or higher, harmful bacteria and microorganisms in the manure can be killed.

According to the different oxygen requirements of microorganisms during the fermentation of livestock and poultry manure, fermentation methods can be divided into aerobic fermentation and anaerobic fermentation. Aerobic fermentation is generally used. For example, the regular turning of the chain plate turning machine allows the materials to fully contact with the air, releasing excess heat while exchanging air. The fermentation tank is a sealed tank and can also use anaerobic fermentation. Anaerobic fermentation microorganisms require suitable living conditions and have certain requirements for temperature, pH and other environmental factors. For example, biogas fermentation belongs to anaerobic fermentation. Organic fertilizer fermentation tanks come in horizontal and vertical types with similar structures. There is an insulation layer outside the tank, which is conducive to fermentation heating and insulation. Therefore, the fermentation production of this equipment is less affected by the external temperature, and continuous production can be achieved throughout the year. There is a stirring shaft inside the tank, and spiral blades are welded onto the stirring shaft. After setting the program, the materials can be stirred regularly to ensure uniform fermentation of the materials in the entire tank. In addition, the whole machine is also equipped with heating pipes and induced draft fans required for aerobic fermentation. This accelerates the trough fermentation method that relies only on microbial fermentation for heating, allowing for rapid decomposition of the materials.

Generally speaking, in the entire tank fermentation process, there will be a manure smell in the early stage and a pungent ammonia smell in the middle stage. Especially for large fermentation workshops, special exhaust ventilation equipment is needed for smooth production. In contrast, the use of organic fertilizer bio-fermentation tanks avoids these hazards, allowing operators to work in a safe and comfortable environment.

In recent years, the fermentation tank industry has developed rapidly. The bio-fermentation tank is equipment for microbial fermentation, which improves fermentation efficiency by optimizing the fermentation conditions of microorganisms. As a high-tech product, the bio-fermentation tank combines fermentation technology with modern biotechnology, gradually changing the past high-energy consumption and high-pollution traditional production model. Fermentation tanks are constantly being upgraded with the development of the times. From traditional fermentation industries to modern fermentation industries, and then to microbial engineering, they have not only become an important pillar of the biotechnology industry but have also combined with genetic engineering technology, making them even more powerful. Bio-fermentation tanks will be widely used in the future, and people should apply them more rationally and scientifically.

Latest News

2025-07-28

The 15th Shanghai International Bio-fermentation Products and Technology Equipment Exhibition 2025 will be grandly held at the Shanghai New International Expo Center from August 7th to 9th.

How can the fermentation system be upgraded?

2022-05-13

Fermentation systems are commonly used in research, production, seed production, and large-scale factory production units for liquid strains. They are also used in the cultivation of various microorganisms, the production of food containing edible fungal active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, commonly used in mycelia.

What are the disadvantages of laboratory fermenters?

2022-04-27

Laboratory fermenters are mainly used in research, production, seed production, and large-scale production units of liquid strains, and are also used in the cultivation of various microorganisms, the production of food containing edible fungus active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, usually in mycelia.

How is the fermentation system managed?

2022-04-21

Fermentation systems are used in the production of food and various dairy products' active factors, so their application is very widespread. Commonly used in mycelia, extracting bioactive ingredients to produce various food additives, extracting bioactive ingredients to produce various food additives, in microbial engineering it is used to produce pesticides, pharmaceuticals, hormones, etc., suitable for scientific research units, and mushroom companies.