What are the three fermentation methods and sterilization procedures for laboratory fermenters?

Release Time:

2021-09-11

What are the three fermentation methods and sterilization procedures for laboratory fermenters?

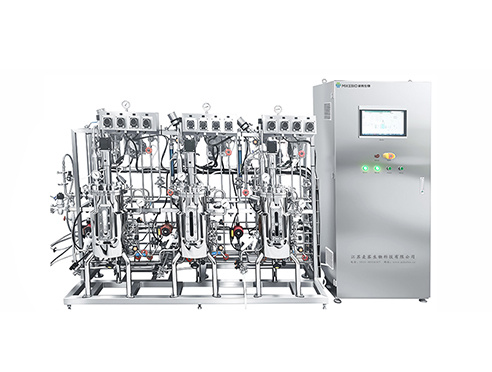

Laboratory fermenters can be divided into aerated fermenters and anaerobic fermenters depending on the needs and anaerobic conditions. Common liquid aerated fermenters can be divided into mechanically stirred, airlift, bubble, and self-priming types according to the aeration method.

Batch fermentation: This method refers to a fermentation method in which the culture medium is added to the laboratory fermenter at one time, and the fermentation is discharged at one time after fermentation. After drainage, the process of adding materials, sterilization, inoculation, and fermentation is repeated. In this process, the growth of bacteria can be divided into four periods: adjustment period, logarithmic period, stationary period, and decline period.

Fed-batch fermentation: This method refers to a fermentation method in which fresh medium is added intermittently or continuously to the batch fermentation. Auxiliary materials can be all materials, such as nitrogen sources, carbon sources, etc. This will prolong the synthesis time of metabolites, etc. This method has increased the production efficiency of penicillin by 20%.

Continuous fermentation: This method is related to a fermentation method in which the old culture medium is continuously discharged and the culture medium is continuously added to the laboratory fermenter. It has the advantages of high equipment utilization rate, stable product quality, and easy automatic control. Its disadvantage is that it is easy to contaminate other bacteria. This technology has been used in the production of yeast cells, ethanol, lactic acid, butanol, petroleum dewaxing, wastewater treatment, etc.

Laboratory fermenters are easily affected by external conditions during fermentation, and it is difficult to perform sterilization operations during fermentation to ensure the hygiene and safety of fermentation products. In liquid fermentation projects, first, the sterilizer should be checked and operated strictly according to the relevant sterilization requirements.

1. After installation, check the electrodes. First, check all interfaces, external circuits, steam pipes, and main valves. The equipment is completely shut down.

2. During sterilization, at least two people should be present, one responsible for the operation of various valves, and the other responsible for checking and reporting various parameters.

3. After confirming that all valves of the laboratory fermenter are closed, open the steam generator inlet valve and start the steam generator. First, the steam generator will automatically add water. At this time, open the bottom drain valve. Try to remove the rust on the steam generator. Then close the drain valve. Pay attention to the water level of the steam generator to prevent turbulence. At this time, fully open the jacket outlet valve, slowly open the steam generator main valve, slowly open the jacket inlet valve, and start to flow steam into the jacket. At the beginning, the steam pressure is unstable, and the pressure gauge pointer may vibrate violently. Before opening the sampling valve and steam outlet, sampling valve and steam inlet, the jacket inlet valve can be properly closed. Both the sampling valve and the lower valve are disinfected, and the unstable steam is discharged at the same time.

Latest News

2025-07-28

The 15th Shanghai International Bio-fermentation Products and Technology Equipment Exhibition 2025 will be grandly held at the Shanghai New International Expo Center from August 7th to 9th.

How can the fermentation system be upgraded?

2022-05-13

Fermentation systems are commonly used in research, production, seed production, and large-scale factory production units for liquid strains. They are also used in the cultivation of various microorganisms, the production of food containing edible fungal active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, commonly used in mycelia.

What are the disadvantages of laboratory fermenters?

2022-04-27

Laboratory fermenters are mainly used in research, production, seed production, and large-scale production units of liquid strains, and are also used in the cultivation of various microorganisms, the production of food containing edible fungus active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, usually in mycelia.

How is the fermentation system managed?

2022-04-21

Fermentation systems are used in the production of food and various dairy products' active factors, so their application is very widespread. Commonly used in mycelia, extracting bioactive ingredients to produce various food additives, extracting bioactive ingredients to produce various food additives, in microbial engineering it is used to produce pesticides, pharmaceuticals, hormones, etc., suitable for scientific research units, and mushroom companies.