Are you familiar with the structural composition and characteristics of laboratory fermenters?

Release Time:

2021-09-14

Are you familiar with the structural composition and characteristics of laboratory fermenters?

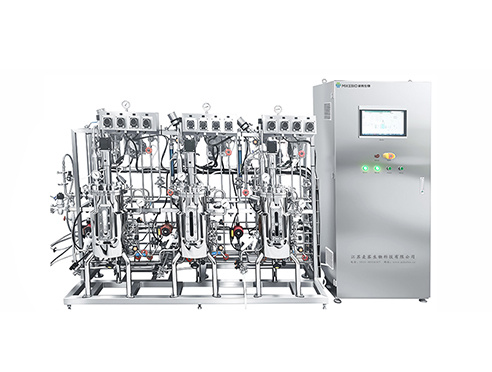

Generally speaking, a laboratory fermenter, based on the form of the fermentation product, is a device that uses various liquid microbial raw materials to prepare a liquid culture medium at a fixed ratio, which is sterilized and then inoculated into a fermenter for fermentation. The above is mainly used for microbial fermentation. The fermenter is made of high-grade stainless steel, with accurate liquid culture medium concentration inside the liquid tank. The mixer inside the tank mixes the materials evenly, and the stirring paddle is used to disperse and break up foam. High dissolved oxygen rate, good mixing effect, promoting material fermentation reaction. It can achieve high-temperature sterilization and prevent material contamination. It complies with national GMP hygiene standards and is widely used in the food, pharmaceutical, and chemical industries.

A laboratory fermenter consists of three main systems: tank body, jacket, stirring system, jacket or coil, transmission device, shaft seal device, insulation, support, fermentation-specific sampling and discharge valve, cooling liquid inlet and outlet, temperature sensor interface, PH automatic control system, pressure sensor, air breather, CIP interface, etc.

The storage tank is generally made of SUS304/SUS316L high-grade stainless steel. The inner cylinder wall is mechanically polished or electropolished, and the outer cylinder wall is insulated by 304 welding. Appearance treatment: mirror polishing or matte polishing. The external connection of the cylinder is a hygienic quick-opening connector that meets national GMP hygiene standards, ensuring safety and hygiene without dead corners.

The laboratory fermenter online control system uses PLC automatic control with a color LCD touch screen to detect and control the relevant parameters of the fermentation process online. The control system includes sterilization interface, parameter setting and correction, data charts, data reports, fermentation batch number setting, online animation, alarm device, etc. It connects with the host, computer, printer, remote monitoring, and data. Storage and printing.

It is also equipped with temperature control devices, thermometer holes, CIP automatic rotating spray balls, antifoaming agents, baffles, air distributors, temperature sensors, sight glass spotlights, liquid level gauges, etc., which are convenient manual devices. Simple and reliable operation.

Structural characteristics of laboratory fermenters:

1. The tank body is made of high-quality stainless steel with polished inner and outer surfaces. Polishing accuracy Ra0.4, anti-sticking wall, easy to clean;

2. The stirring system adopts a three-layer six-flat-blade fermentation-specific standard paddle, and stepless speed regulation can realize fully automatic control of the fermentation stirring process; the structure is reasonable, easy to disassemble and assemble, with an automatic lifting device, convenient and safe to use;

3. The laboratory fermenter uses high-temperature steam sterilization, and the sterilization process is automatically controlled, with accurate sterilization temperature;

4. Swiss Mettler PH electrode and shielded wire, with a range of 2-12PH and a control accuracy of 0.02PH;

5. Antifoaming agent can be added to detect foam automatically, with a sensitivity of 100-10000; gas flow control can be manually adjusted according to the rotor flow meter, ranging from 0-5000 liters/minute; 6. The supply system can be automatically supplied by a perturbation pump, ranging from 0-5L/min, with a control accuracy of 2%.

Latest News

2025-07-28

The 15th Shanghai International Bio-fermentation Products and Technology Equipment Exhibition 2025 will be grandly held at the Shanghai New International Expo Center from August 7th to 9th.

How can the fermentation system be upgraded?

2022-05-13

Fermentation systems are commonly used in research, production, seed production, and large-scale factory production units for liquid strains. They are also used in the cultivation of various microorganisms, the production of food containing edible fungal active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, commonly used in mycelia.

What are the disadvantages of laboratory fermenters?

2022-04-27

Laboratory fermenters are mainly used in research, production, seed production, and large-scale production units of liquid strains, and are also used in the cultivation of various microorganisms, the production of food containing edible fungus active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, usually in mycelia.

How is the fermentation system managed?

2022-04-21

Fermentation systems are used in the production of food and various dairy products' active factors, so their application is very widespread. Commonly used in mycelia, extracting bioactive ingredients to produce various food additives, extracting bioactive ingredients to produce various food additives, in microbial engineering it is used to produce pesticides, pharmaceuticals, hormones, etc., suitable for scientific research units, and mushroom companies.