How is a liquid fermenter installed?

Release Time:

2022-04-15

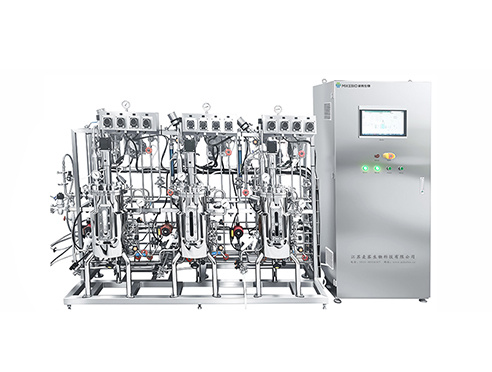

Liquid fermenters are commonly used in research, production, seed production, and large-scale industrial production of liquid strains. They are also used in the cultivation of various microorganisms, the production of foods containing active ingredients from edible fungi, and the production of active factors in various dairy products. Therefore, their applications are very widespread, commonly used in mycelia.

If your work requires edible fungus fermenters, you must purchase them from a reputable manufacturer to ensure product quality. Our company has a fermentation pilot plant, which integrates intelligence and automation, and has built a mature fermentation system. It can complete the entire process of commissioned development, from small-scale fermentation process optimization and pilot-scale fermentation production to the separation and purification of fermentation products. We have also established a postdoctoral workstation and a modern laboratory.

Steam should be used to sterilize the air filter connected to the bioreactor, and air should be used for drying. Simultaneously with the sterilization of the tank itself, wastewater should be drained and flushed from the transport pipes. Then, the prepared culture medium should be pumped into the fermenter, and the agitator should be started for sterilization. Sterilization of the bioreactor: First, open all exhaust valves, introduce steam into the jacket or coil for preheating. When the tank temperature rises to 80-90°C, gradually close the exhaust valves after removing them.

Latest News

2025-07-28

The 15th Shanghai International Bio-fermentation Products and Technology Equipment Exhibition 2025 will be grandly held at the Shanghai New International Expo Center from August 7th to 9th.

How can the fermentation system be upgraded?

2022-05-13

Fermentation systems are commonly used in research, production, seed production, and large-scale factory production units for liquid strains. They are also used in the cultivation of various microorganisms, the production of food containing edible fungal active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, commonly used in mycelia.

What are the disadvantages of laboratory fermenters?

2022-04-27

Laboratory fermenters are mainly used in research, production, seed production, and large-scale production units of liquid strains, and are also used in the cultivation of various microorganisms, the production of food containing edible fungus active ingredients, and the production of active factors in various dairy products. Therefore, its application range is very wide, usually in mycelia.

How is the fermentation system managed?

2022-04-21

Fermentation systems are used in the production of food and various dairy products' active factors, so their application is very widespread. Commonly used in mycelia, extracting bioactive ingredients to produce various food additives, extracting bioactive ingredients to produce various food additives, in microbial engineering it is used to produce pesticides, pharmaceuticals, hormones, etc., suitable for scientific research units, and mushroom companies.