Product Categories

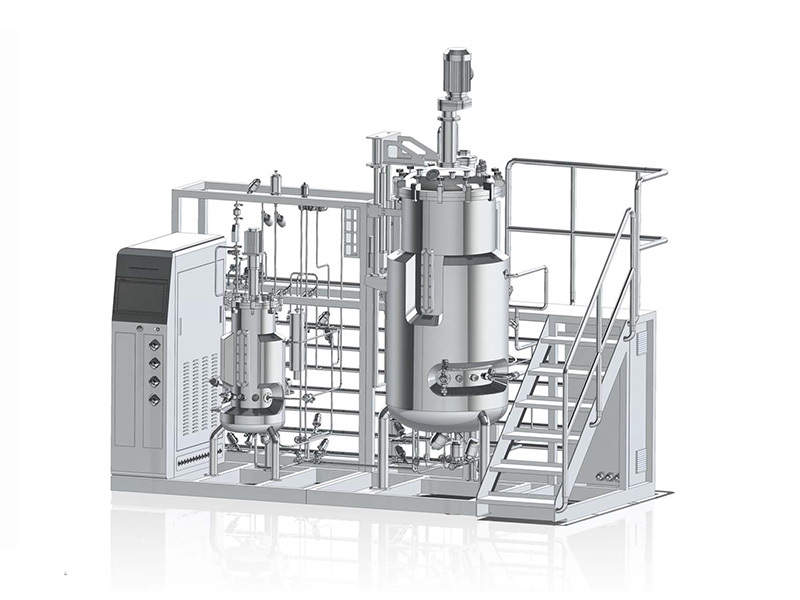

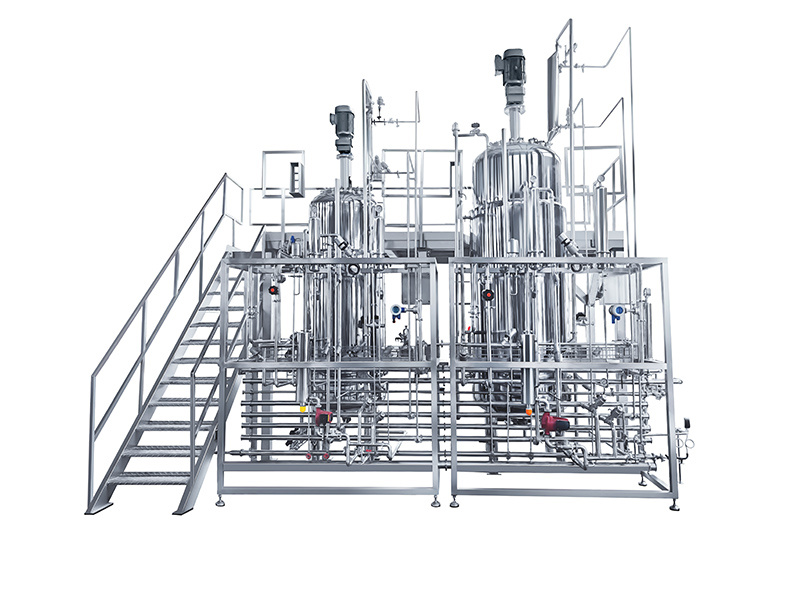

Large-scale Automatic Fermentation Equipment

Summary: Core equipment specially designed for large-scale industrial fermentation. Integrates advanced automation control and high-quality stainless steel structure to ensure high stability and high-efficiency production, meeting the stringent output and quality requirements of the food, pharmaceutical, and biotechnology industries.

Category: Production Fermentation Equipment

Product Details

Product Introduction

Core equipment specially designed for large-scale industrial fermentation. Integrates advanced automation control and high-quality stainless steel structure to ensure high stability and high-efficiency production, meeting the stringent output and quality requirements of the food, pharmaceutical, and biotechnology industries.

Product Features

• Intelligent Control: PLC + touch screen for full automatic monitoring and adjustment of key parameters such as temperature, pH, and dissolved oxygen. Data is traceable to ensure batch stability and continuous production.

• Clean and Reliable: Main body made of 316L stainless steel, easy to clean, corrosion-resistant, compliant with strict hygiene standards, reducing contamination risks and ensuring product compliance.

• Efficient and Stable: Optimized stirring and mass transfer design to improve production efficiency; robust structure ensures long-term reliable operation and guarantees capacity.

• Flexible Expansion: Modular design supports configuration and upgrades according to production line needs, adapting to future scale growth.

Product Features

• High-quality stainless steel tank body, corrosion-resistant, easy to clean, compliant with production standards.

• Well-designed stirring system ensures uniform mixing of the culture medium, enhancing the transfer efficiency of gases and nutrients.

• Data Collection and Analysis: Records various parameters during fermentation for convenient subsequent process analysis and optimization.

Product Parameters

| Model | MKY-ATS | Tank Material | Cylinder 316L / Jacket 304 |

| Volume | 1~200m³ | Stirring Method | Mechanical Stirring |

| Filling Coefficient | 40-75% | Drive Mode | Frequency Converter |

| Sealing Method | Mechanical Seal | Sterilization Method | In-place Sterilization |

| Control Method | PLC + touch screen, full-process automatic control / automatic fermentation process control | ||

| Basic Configuration | Temperature, pH, dissolved oxygen, defoaming, feeding, rotation speed, air flow, sterilization, tank pressure, air intake filtration | ||

| Optional Configuration | OD, ORP, conductivity, liquid level control, tank weighing, feeding weighing system, multiple gas channels, multiple feeding channels, exhaust gas analysis, etc. | ||

keyword: Large-scale Automatic Fermentation Equipment

Related Products

Product Consultation

If you have any suggestions, please leave a message or email us, and we will reply to you within one working day of receiving your message.